Materials

OÜ Feature sells materials for any kind of printed products from leading manufacturers. A wide range of our materials allows customers to any printed work in many areas, especially in the production of identity and security documents, where levels of protection papers and documents should differ in effectiveness and uniqueness differ in terms of data protection, while still having a reasonable manufacturing cost.

OÜ Feature sells materials for any kind of printed products from leading manufacturers. A wide range of our materials allows customers to any printed work in many areas, especially in the production of identity and security documents, where levels of protection papers and documents should differ in effectiveness and uniqueness differ in terms of data protection, while still having a reasonable manufacturing cost.

Our company also sell polycarbonate films such brands, Lexan ™.

Lexan ™ polycarbonate films possess a number of valuable properties: transparency, high mechanical strength, high resistance to shock loads, low water absorption, high electrical resistivity and dielectric strength, small dielectric loss over a wide frequency range, high heat resistance, products made of it are stable characteristics and sizes wide temperature range (-100 to + 135 ° C).

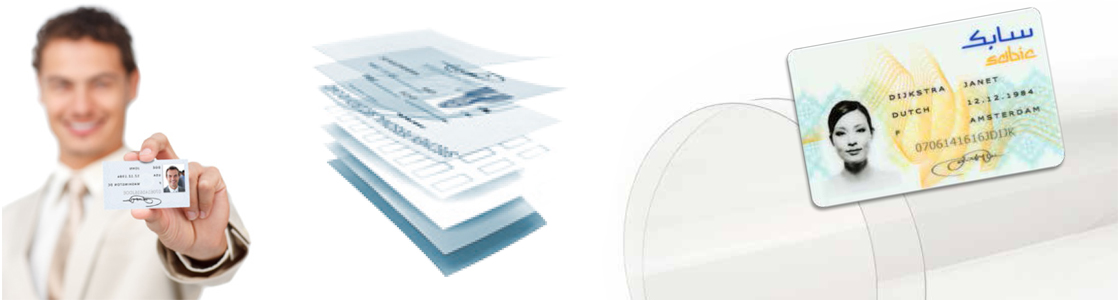

A high-performance polycarbonate LEXAN™ SD film portfolio specially designed for electronic ID cards, government, military and police ID cards, passport data pages, green cards, border crossing cards and driver’s licenses. LEXAN Secure ID film portfolio includes a clear lasermarkable layer, co-extruded layers, a bright white core layer, flexible coated overlays and a clear overlay grades for the cover or intermediate layers. These films deliver tight gauge tolerances to simplify manufacturing of cards within mandated thickness parameters providing our customers significantly higher productivity.

Lexan can be divided into three main segments:

- Transparent polycarbonate film from both sides,

- Transparent polycarbonate film on one side and matt on the other hand,

- Transparent polycarbonate film matt on both sides.

Lexan polycarbonate films have over thirty different models

Graphic polycarbonate films LEXAN - the most widely used series of polycarbonate films. Usually all the films in this series are based on a single transparent base film, which is excellent for printing UV- curable ink. The film may be produced in a wide range of thicknesses from 125 microns to 750mkm, it can be applied to several types of embossments.

Graphic polycarbonate films LEXAN - the most widely used series of polycarbonate films. Usually all the films in this series are based on a single transparent base film, which is excellent for printing UV- curable ink. The film may be produced in a wide range of thicknesses from 125 microns to 750mkm, it can be applied to several types of embossments.

The most common brand of graphic polycarbonate LEXAN:

- 8B35E

- 8B36

- 8A35

- 8A13E

- 8A73

The main parameters of graphic polycarbonate films:

- Thickness range from 75mkm to 750mkm

- Available roll width - 920mm and 1220mm

- Thermal stability - 160 ° C

Types of embossing applied to the polycarbonate film LEXAN:

- VELVET

- SUEDE

- MATT

- FINE MATT

- OPAC

- EMPY

The films can also vary the degree of surface gloss and light transmission rates.

The majority of the films of this type finds its application in the field of advertising and scope of protective lamination.

SABIC’s Lexan™ security and ID card film portfolio has been specially designed for easy manufacture and lamination of complex secure ID cards. It includes a lasermarkable grade, a bright white (opaque) grade, a clear grade for the cover or intermediate layers, co-extruded film and flexible hard-coated film.

These products directly address accelerating industry trends calling for more and thinner card layers to accommodate additional safety features, provide easy processing and enhanced durability for ID cards and other security documents.

With their light weight, high impact resistance and high optical quality, Lexan™ and Margard™ sheet materials are often a top choice for lamination applications. Lexan sheet combines crystal clear transparency with value-added performance that features outstanding ripple, distortion and optical defect characteristics.

OÜ Feature guarantees an individual approach to each client in the complex selection of materials for the production of a specific product, taking into account peculiarities of production and material requirements.

OÜ Feature guarantees an individual approach to each client in the complex selection of materials for the production of a specific product, taking into account peculiarities of production and material requirements.

Our company policy - is to create a flexible work environment with every customer, so we are willing to consider non-standard conditions for the supply of materials to adhere to the optimal plan for the client. For regular partners are special discounts.